Safety culture

A good safety culture is an essential element of the core expertise of Posiva professionals. It consists of personal competence, general attitudes, efficient operating models created by the organisation, and supporting instructions. Building a good safety culture requires continuous and systematic improvement and measurement.

In order to develop its safety culture, Posiva has prepared an action plan, which is updated on an annual basis with key development measures in order to develop safety in accordance with the principle of continuous improvement. In terms of developing the safety culture, it is important to increase related expertise and influence safety-related attitudes through training, for example. Posiva uses the three-tier scale of the International Atomic Energy Agency (IAEA) as the basis for assessing the state of the safety culture.

As part of its safety culture action plan, Posiva organises a self-assessment of safety culture every three years, along with a safety culture survey through which employees can evaluate the safety culture based on predefined criteria and their own experiences. According to the latest survey, the state of safety and safety culture at Posiva is good.

In terms of the safety-related challenges, Posiva’s geological final disposal activities are vastly different from nuclear power plant operations, which necessitates special considerations in the context of safety management. In addition to the applicable nuclear and radiation safety criteria, Posiva has used various naturally-occurring changes (including future icee ages up to a million years from now) as the design bases for the final disposal solution. The safety case documents have analysed how well the final disposal solution will withstand earthquakes or loads caused by glaciers, for example. Constructing repositories in bedrock that is about 1,800 million years old requires the management of safety-critical functions to ensure that the intact zones of the rock remain suitable for final disposal. Posiva must also make sure that, once the final disposal period is over, the bedrock will be as intact as it was before excavation.

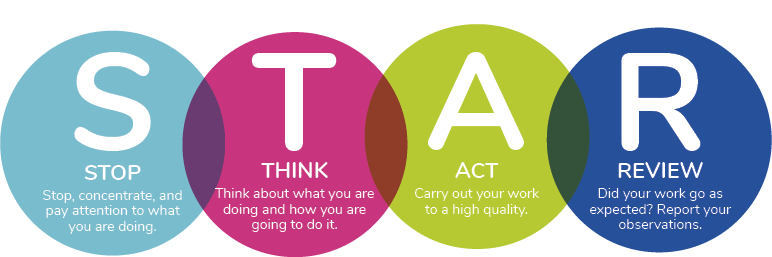

From the perspective of occupational and fire safety, building final disposal facilities underground is a challenging task, which is why particular attention has been paid to personal and fire safety. As such, Posiva encourages its personnel and partners working in Olkiluoto to report any safety deficiencies. The company maintains a low threshold for reporting safety deviations, which ensures that all parties concerned can contribute to the continuous improvement of safety. The STAR principle is applied to all work tasks. It states that, in unexpected situations, you must always Stop and Think first, then Act and finally Assess whether or not everything was done correctly.