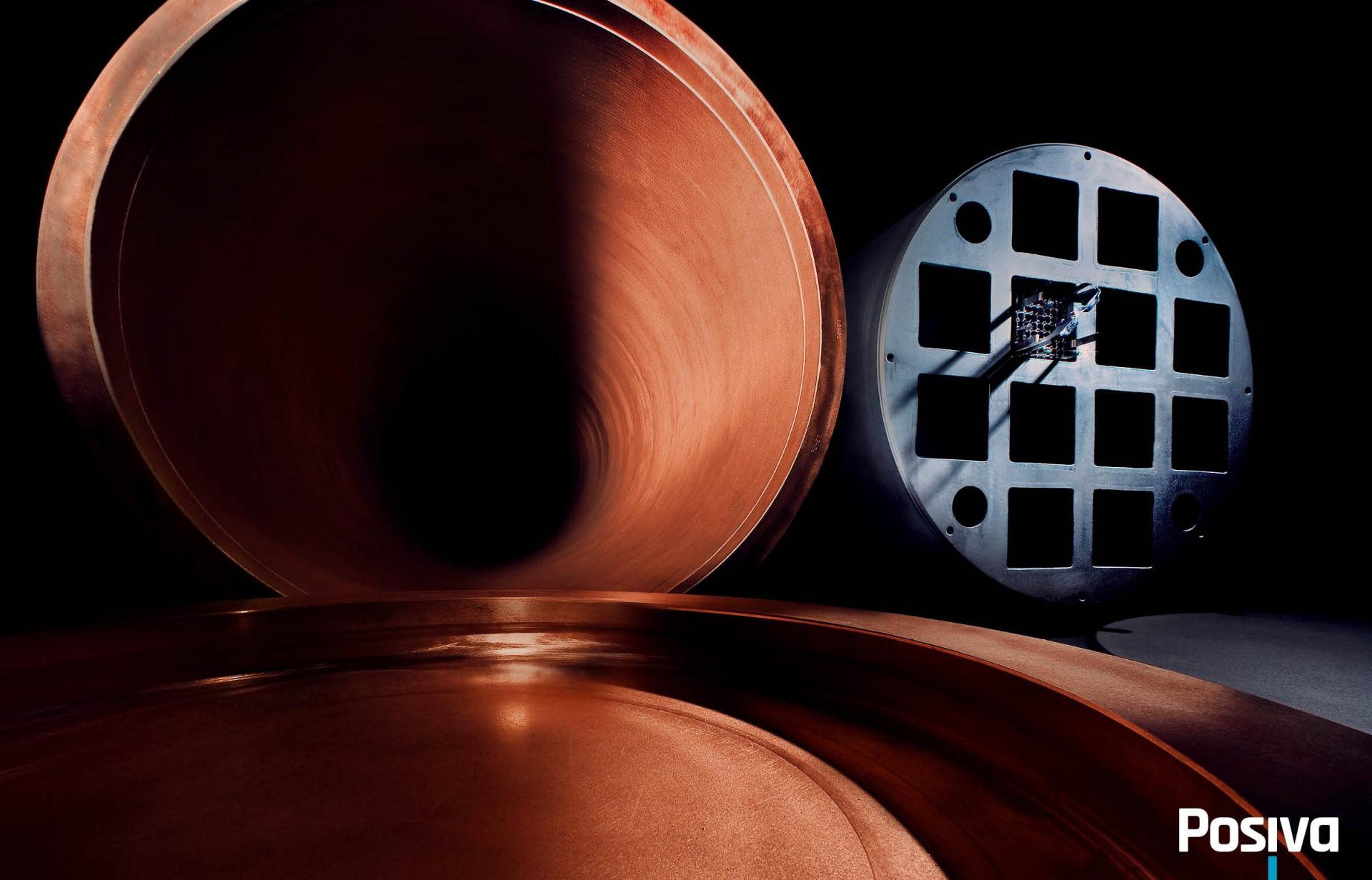

Disposal canister

The inner structure of the spent fuel disposal canister comprises a spheroidal graphite cast iron component, which serves as the load-bearing component of the canister and as the fuel element placement rack. The sealed copper canister has been designed to act mainly as a corrosion barrier for the cast iron inner part, which in turn contains the fuel elements. The inner structure is sealed with an steel lid. The inner structure of the canister is surrounded by a 5-cm thick copper shell and a copper lid.

In final disposal, the length of the canister varies depending on where the spent fuel comes from. The canister of the Olkiluoto 1 and 2 plant units (OL1, OL2) holds 12 fuel assemblies and it is 4.75 m long. The canister of Loviisa (LO1, LO2) holds 12 fuels assemblies and it is 3.6 m long. The canister of the Olkiluoto 3 (OL3) plant unit holds four fuel assemblies and it is 5.2 m long. The diameter of the canister is always 1.05 m.

The total weight of the final disposal canister depends on which plants’ spent fuel is placed inside it. For example, the total weight of the final disposal canister of the OL1 and OL2 power plant units is 24.5 t.

Spent nuclear fuel elements are installed and sealed inside the cast iron inner part of the copper canister. The lid of the copper canister is tightly sealed by welding so that groundwater flowing in bedrock cannot get in contact with the cast iron inner part or spent fuel. This will prevent radionuclides from getting into groundwater and then into the geosphere and biosphere.