ONKALO® bottom soon accessible in little over one minute – testing of personnel lift almost completed

Access to ONKALO will soon be much easier, thanks to the brand-new personnel lift. The functional testing of the lift is approaching completion with preparations started for the pre-commissioning inspection. The unique lift is designed and manufactured by KONE Oyj.

Project Manager Jarno Säippä with the personnel lift currently undergoing functional testing in the background. The lift travels to the bottom of ONKALO in about 70 seconds.

The bottom is a long way away. The lowest stop for the lift is located 437 metres below ground level. And as the top of the lift shaft is 13 metres above ground, the total travel of the lift is 450 metres.

To understand the scale, it can be compared to the tallest residential building in Finland, the 35-storey Majakka completed in the Kalasatama area of Helsinki in 2019 which stands at 134 metres tall. The lift to Onkalo travels a distance more than three times that.

The new lift will shorten commuting time nicely. By car, the bottom of ONKALO can be reached in about 20 minutes.

- The travel speed of the lift is eight metres per second (29 km/h), which means the travel time is now a little over one minute, calculates Project Manager Jarno Säippä from Sitowise Oy. This also makes it the fastest lift for customer use in Finland. For example, the travel speed of the lifts in the Näsinneula Tower in Tampere, upgraded a couple of years ago, is "only" six metres per second.

Multiple lift cars a special feature

Project Manager Säippä tells that the installation of the personnel lift started in January 2022.

- The biggest challenges concerned the steel frame surrounding the lift that acts as the mounting base for the guides in which the lift car runs, he explains.

The brand-new personnel lift features two separate lift cars designed for passengers. Each has a capacity of 20 persons (2x 1500 kg). The lift stops on a total of 10 levels.

- The lower lift car can be used to access the controlled area facilities, while the other car stops by the uncontrolled areas, Säippä presents.

The lift also features a third car, designed for maintenance purposes. It is the lowermost of the lift cars. This will facilitate visual inspections of the shaft as well as other maintenance activities. The steel structure of the lift shaft houses also a lot of other equipment, such as HVAC and electrical systems.

Smooth ride ensured by recent innovation

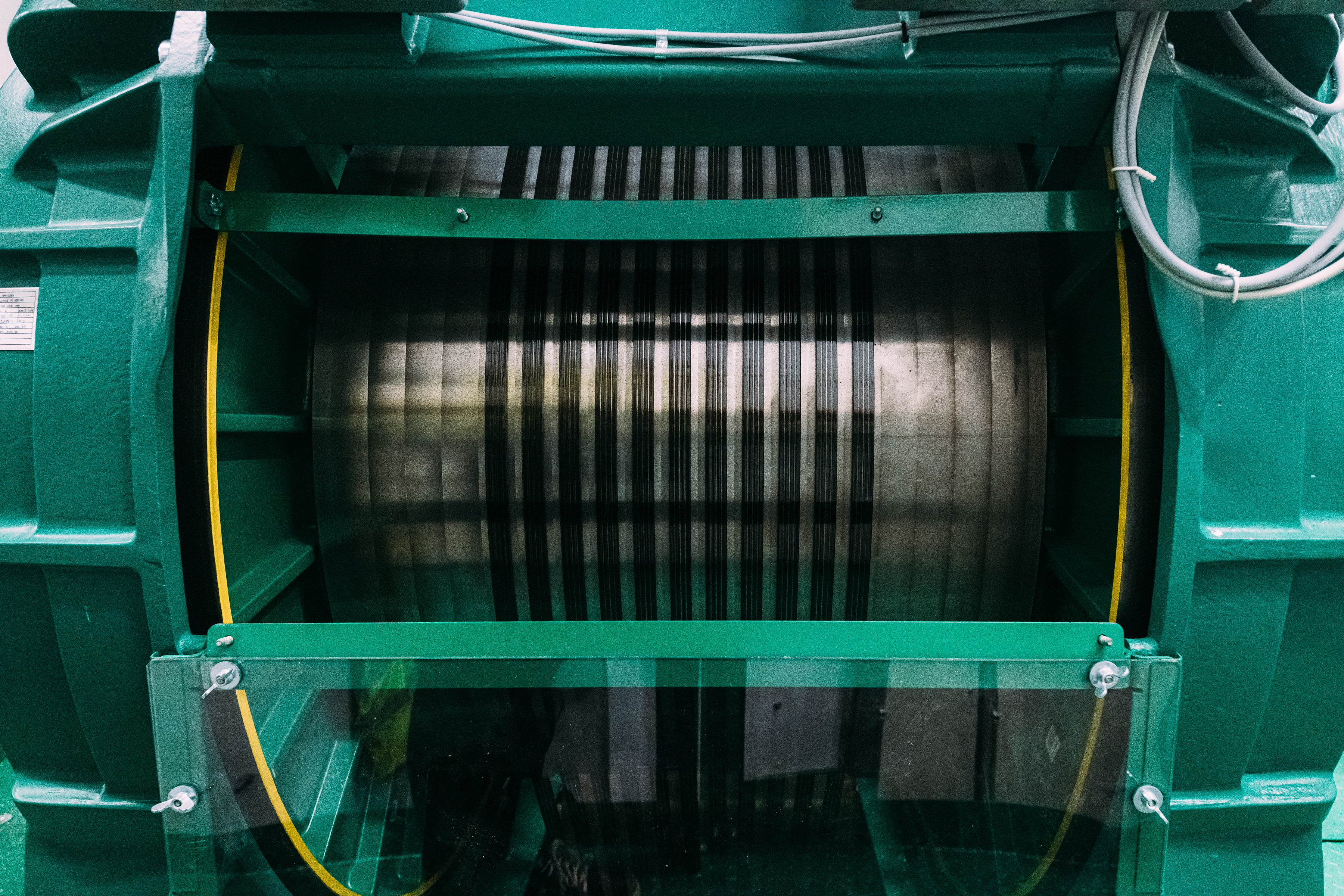

One of the special features of Posiva's lift is the UltraRope technology which is KONE's own innovation.

- UltraRope is made of carbon fibre reinforced polymer with a high-friction coating. It is considerably lighter than conventional steel rope, weighing only about a fifth of the weight of steel, says Project Manager Jarno Säippä.

The innovation reduces the weight of the lift significantly. A conventional steel rope of this length would weigh about as much as an articulated lorry. Owing to the special coating, the rope requires no lubrication either, and boasts a service life at least twice as long as that of conventional steel rope.

According to the Project Manager, the lift offers a very smooth ride.

- If looking for excitement, the rides of amusement parks beat this lift 100-0.

In addition to the personnel lift, work is ongoing also on the canister lift at the final disposal facility. As suggested by the name, it is designed for transferring the final disposal canisters. The canister lift moves clearly slower, at a speed of about one metre per second. But then the cargo it carries is very different, too. One canister weighs ca. 30 tons. The commissioning of the canister lift is scheduled for next year.

Text: Ville Kulmala

Photos: Tapani Karjanlahti

Share