Posiva's machining station arrives in Olkiluoto in April

For Posiva, the year 2023 is very much about machines. Whereas last year saw the completion of building work at the encapsulation plant, this year is characterised by the installation and erection of multiple machines and equipment. One of these is the robotic machining station expected to arrive in Olkiluoto in April. According to plans, it will be ready for operation before the summer.

The machining station plays a key role in the final disposal process. In addition to actual machining operations, the fuel canisters for final disposal are inspected at the station to verify their surface quality and absence of welding defects as well as the dimensions of the canister, down to a hundredth of a millimetre.

In the overall process at the encapsulation plant, the main function of the machining station follows after the canister has been welded closed. However, the robot is involved in the overall process of the machining station already for operation before that. It takes a sample of the canister surface for contamination analysis before the canister moves to the welding station, and also decontaminates it, if necessary.

Approximately four-hour operation

After the welding stage, the canister enters the actual machining operation. It begins with the verification of both canister temperature and precise dimensions. These are used to specify exact, canister-specific machining parameters for the canister machining operation. All in all, the machining operation consists of six different work phases with a total duration of about four hours. Thanks to robot integration, the entire process is automatic, including even the removal of milling chips.

Before returning to the transfer corridor, the canister also undergoes accurate NDT inspections (Non-Destructive Testing) which in practice are designed to verify that the weld is free from defects. In fact, this is an important reason for the canister being machined in the first place. Without the smooth surface produced through machining it would not be possible to verify the weld quality.

The smoothness of the surface also serves another purpose. It ensures the fluent movement of the canister through the remaining parts of the encapsulation process.

Ready for operation by summer

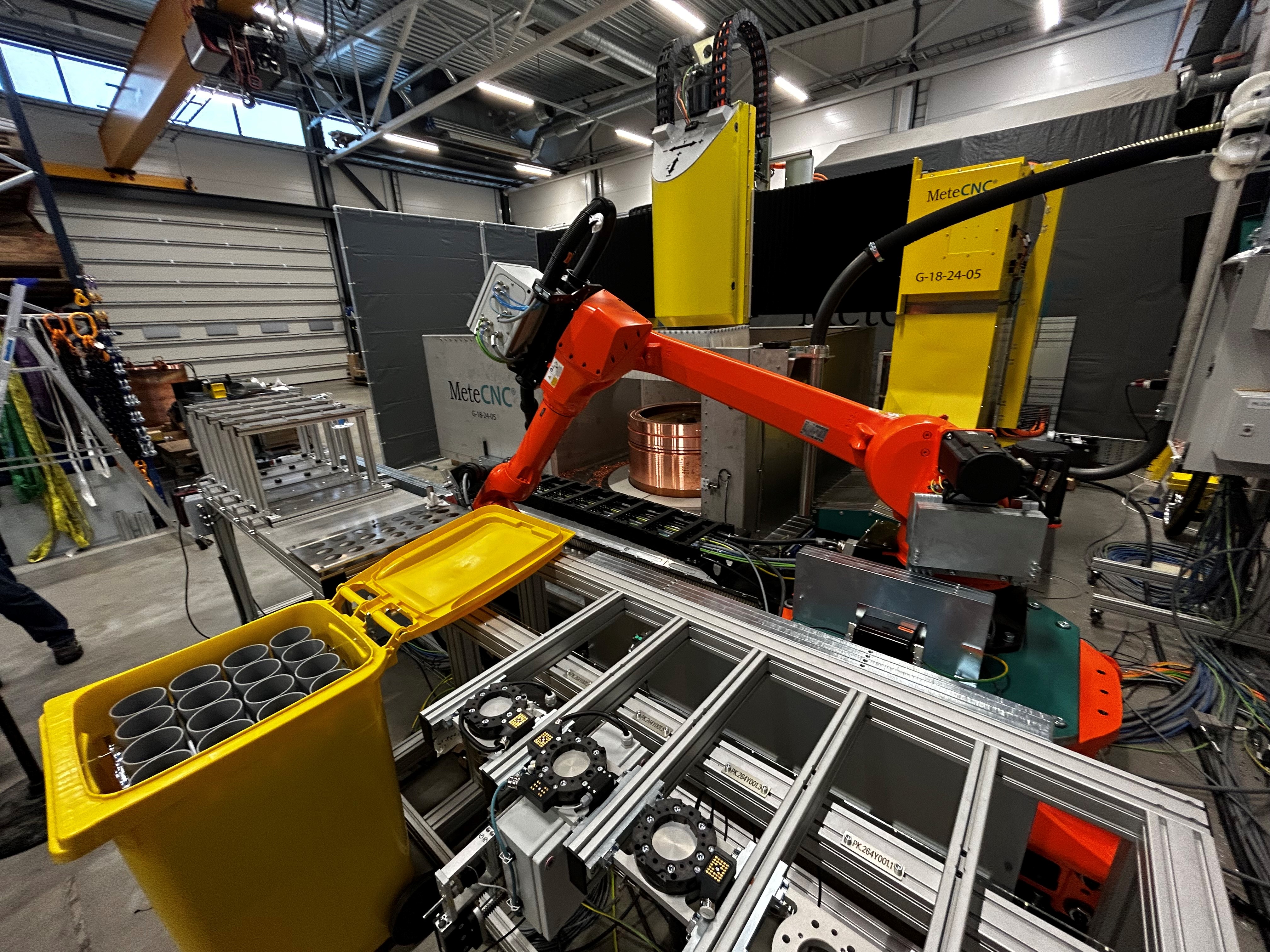

The machining station was manufactured for Posiva on special order by Metecno Oy. Some components were still added and adjustments made to the station during the first months of 2023 in Metecno's facilities in Nokia. Matti Metsähonkala, the CEO of Metecno, says that erection work can start in April.

Before that, however, the machining station had to be taken apart into smaller units for the transfer. Two full trailers are barely enough for transport because of the large size of the machining station.

Metecno will send a crew of six to Olkiluoto. In addition to erection work, operator training is also to be provided.

- The station will be ready for operation by the summer, Metsähonkala guarantees.

A more comprehensive article on the machining station can be found in TVO Group's Newsletter 1/2023 which will be published on in mid-April. To receive the Newsletter by email, subscribe to it hereOpen link in a new tab.

An overview of the operation of the encapsulation plant as a whole, including also the role that the machining station plays, can be found by from this linkOpen link in a new tab.

Text and photos: Ville Kulmala

Share