A canister only becomes a canister after friction stir welding

The canister containing Posiva’s spent nuclear fuel is transferred from the encapsulation cell along the canister transfer corridor to the machining station where the surface of the canister is cleaned, if necessary, based on a contamination sample taken from the top part of the canister. The lid of the canister insert has at this point already been screwed in place and closed.

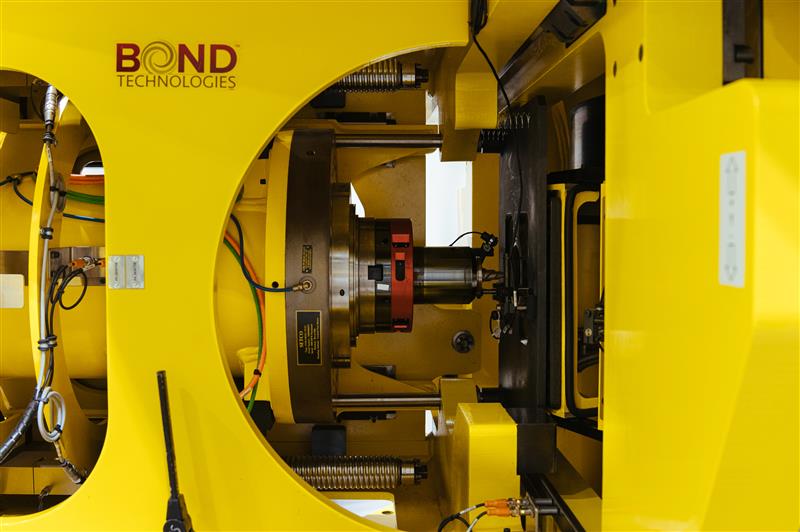

Machining station for final disposal canister

The canister continues from the machining station to the welding station for the installation of the copper lid on the top of the canister. The lid is then closed by friction stir welding.

After welding, the canister returns to the machining station where the top part of the canister is machined. In practice, this means that any excessive copper is removed from the surface of the canister. The previously welded area is also machined to allow the tightness of the weld to be inspected using eddy current and ultrasonic methods in addition to a visual inspection. The sealing joint on the copper lid produced by the selected friction stir welding method has an integrity comparable to that of the canister mantle.

- Tightness is of key significance in the encapsulation process. It can be said that a canister only becomes a canister after friction stir welding. It becomes a single assembly whereas before welding it is “a number of loose parts”, explains Oskari Piepponen, Welding Engineer and Welding Coordinator from Posiva.

The smooth surface also ensures the fluent movement of the canister through the remaining parts of the encapsulation process. Once the weld has been demonstrated to conform to requirements, the canister can be sent further along the process. If the weld is found to be defective, the canister can be machined open at the machining station, if necessary.

Posiva Oy is the leading final disposal operator in the world, about to start in the mid-2020s the final disposal of spent nuclear fuel in the ONKALO® facility excavated deep in the bedrock.

Friction stir welding machine at the machining station

Posiva Oy animation of the Encapsulation plantOpen link in a new tab

Text: Pasi Tuohimaa, photos and video: Tapani Karjanlahti

Share