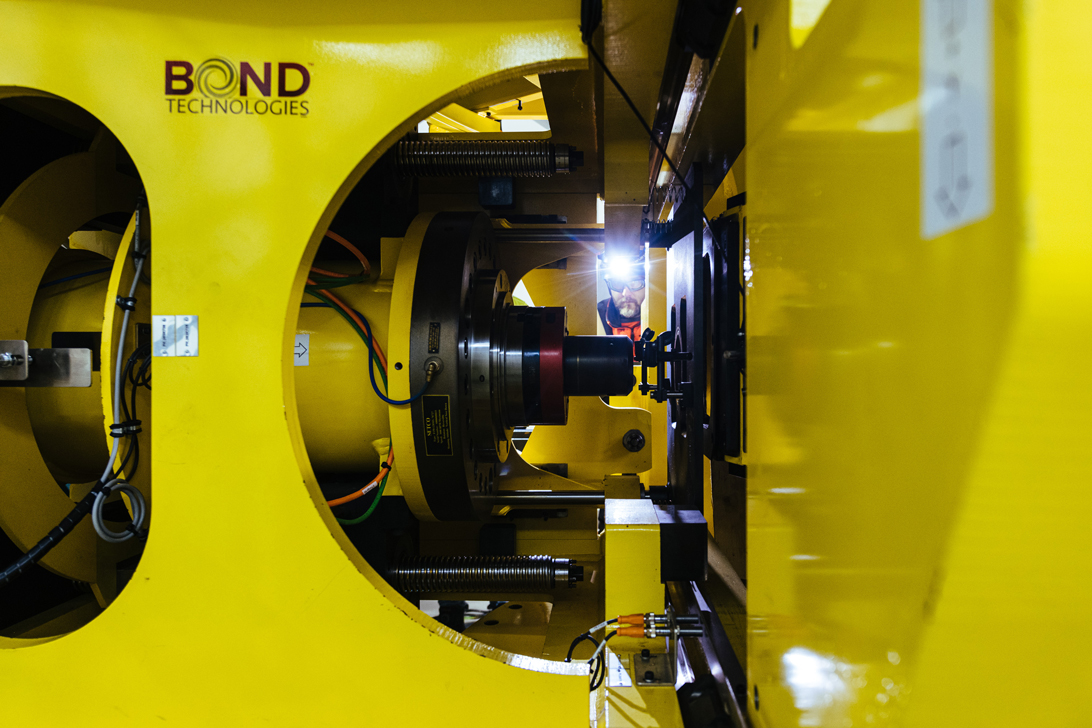

Laser beam identification of start hole in welding of canister lid

Precise, complex, and controlled. Posiva’s own testing of the lid welding station at the encapsulation plant for spent nuclear fuel has reached the stage where preparations are made for the qualification of the operators in charge of the welding of the lid.

The image in the video shows the use of a laser beam to identify the start hole in the welding of the canister lid. In practice, this is part of the preparations for the SAT (Site Acceptance Test). The SAT stage will ultimately be concluded with a weld made on a full-scale final disposal canister.

- The successful performance of the laser beam identification of the start hole in welding is an important step in ascertaining that we can proceed with the SAT stage, says welding engineer Oskari Piepponen who works with the process systems of the encapsulation plant.

According to Piepponen, the tests related to the welding of the lid have progressed well with respect to the actual welding machine. The integration of the machine with the other systems of the encapsulation plant, however, is an extensive process of its own.

- Staff from the supplier of the welding machine, the US company Bond Technologies, just spent three weeks here and considerable improvements that were clear to see were made during that time in bringing the machine toward SAT readiness.

A representative from the machine supplier will be present also when the final SAT stage approval of the welding station of Posiva’s encapsulation stage takes place in the near future.

Posiva Oy animation of the Encapsulation plant (youtube.com)Open link in a new tab

Text: Pasi Tuohimaa

Photo and video: Tapani Karjanlahti

Share