Transfer trolley of fuel transport cask moved in place at encapsulation plant

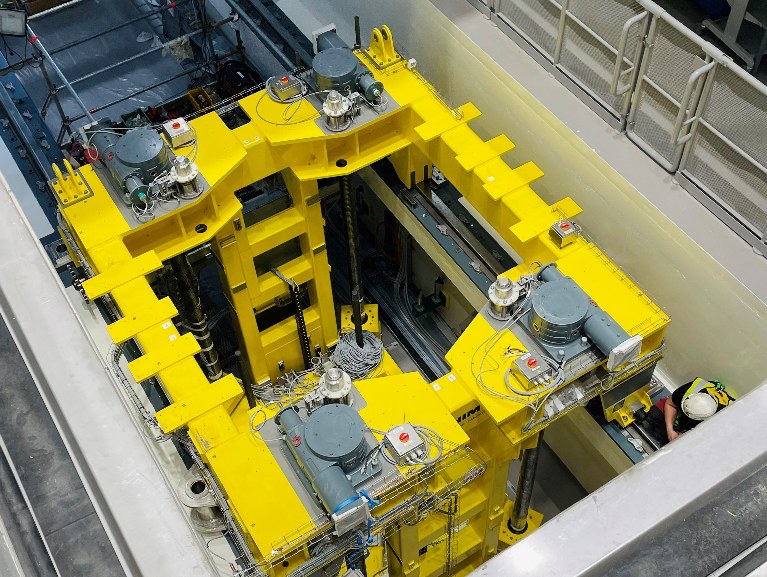

Installation work is progressing at the encapsulation plant for spent nuclear fuel. On Friday, 2 February, the transfer trolley of the fuel transport cask was moved from the fuel reception hall one storey down and placed on rails. It was quite a task, as the transfer carriage weighs approximately 30 tons, equivalent to that of a bus.

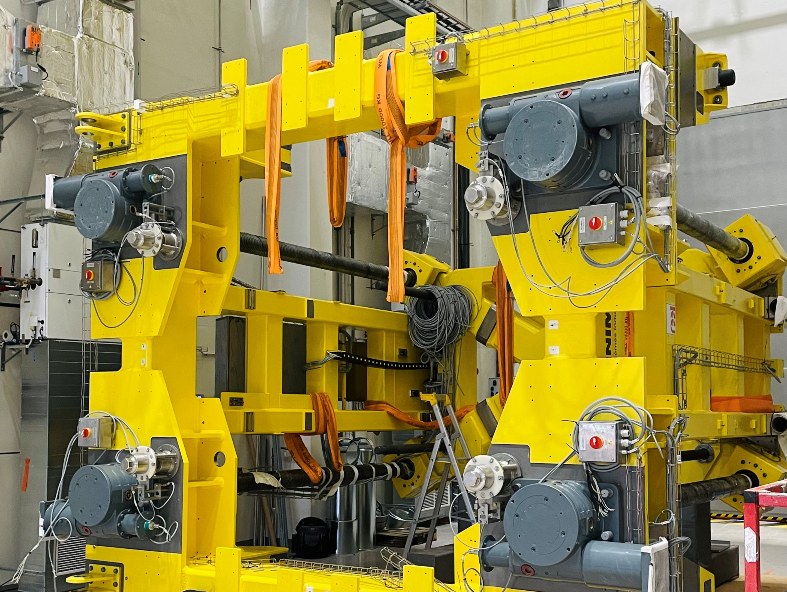

Transfer trolley for fuel transport cask ready to be lifted and mounted in place. The stepladder inside the trolley gives an idea of its dimensions.

- This is yet another important milestone at the encapsulation plant. Having the equipment specifically designed for this purpose ready for operation and in place and installation work progressing at good pace is a major accomplishment, says Installation Manager Veijo Ruotanen who is in charge of the installation of the main equipment at the encapsulation plant.

The fuel transport tank transfer carriage that arrived at the encapsulation plant in early February was manufactured by the French company CSI. The height of the approximately 30-ton carriage is about five meters, and its width is four meters.

The transfer carriage plays both a central and versatile role in the final disposal process. It not only receives the tank upon its arrival but also transfers, lifts, and docks the tank into the docking station. One challenge is that all of this takes place in a rather compact space within the transfer corridor.

The fuel transport cask transfer trolley is the first link in the spent fuel handling phase. The spend fuel is transported to the encapsulation plant from TVO’s interim fuel storage using a transport cask.

A docking preparations station is provided between the reception point and the docking station, where maintenance activities and measures that prepare the cask for docking and undocking are carried out on the cask.

The rails downstairs are ready to receive the transport cask transfer trolley.

Watch video of Posiva Oy animation of the Encapsulation plantOpen link in a new tab

Text and photos: Pasi Tuohimaa

Share