Posiva’s project makes progress also with underground production equipment

Posiva’s project for the final disposal of spent nuclear fuel is making progress also as far as the underground production equipment is concerned. Posiva has completed the procedure qualification test on backfill installation, during which almost 12 tunnel metres were filled with backfill clay using the GBIS backfill installation system. The minimum goal for the test that took about three weeks was to fill a length of at least 10 metres of the tunnel.

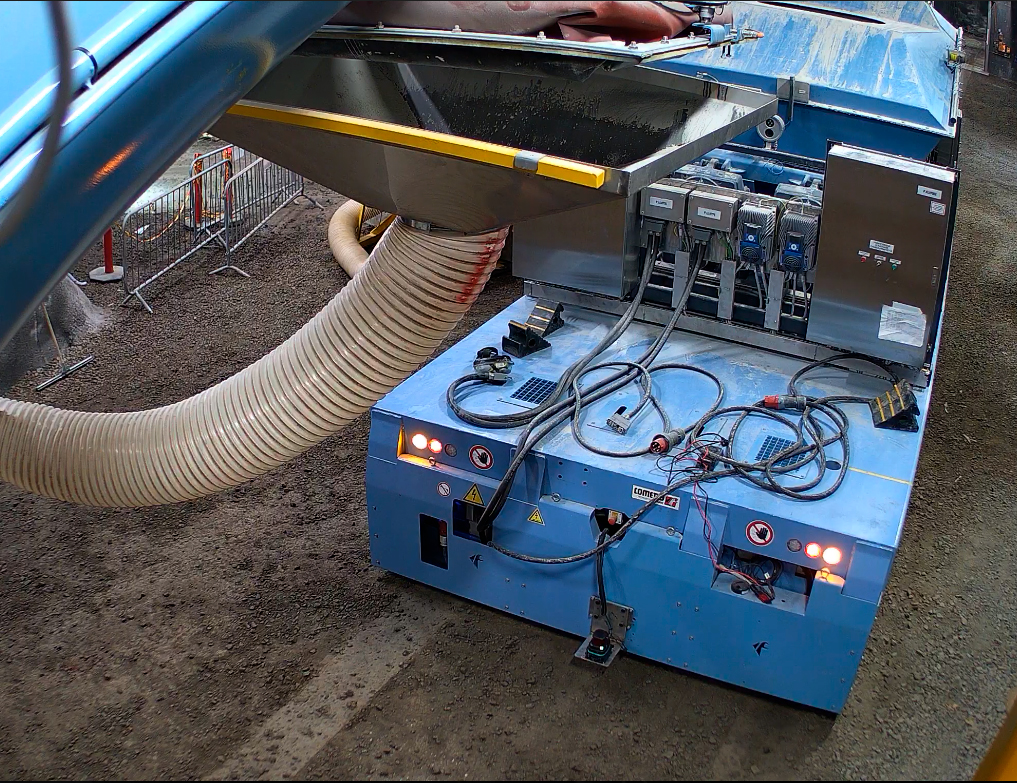

The tunnel filling installation system is a large and long combination of machines that fills almost the entire tunnel.

The actual test acceptance criterion was to achieve a tunnel backfill degree of a minimum of 98 percent. Analyses that are still to be verified indicate that the achieved backfill degree exceeded this criterion.

The procedure qualification test on backfill installation was designed to demonstrate the operability of the systems and equipment in tunnel conditions at a depth of 435 metres in the bedrock. Another requirement was to achieve the specified result deploying the operating methods and procedures that will be deployed also during production.

Development Manager Ari Maarni from Posiva describes the test and the underground conditions challenging.

- The large, long combination machine almost fills the entire tunnel and compacts clay with large screws while pushing it into the tunnel. At the same time, it reverses slowly in order to achieve a uniform backfill degree. During the test, the transfer vehicle ran autonomously between the discharge station and the installation machine supplying more clay to the installation machine. We did not have any criteria for the rate of backfill, Maarni says.

According to Maarni, the biggest challenges during the test were caused by the uneven bottom of the tunnel.

- The docking of the transfer vehicle to the installation machine was difficult in points with large surface height differences. This slowed down the work. However, as the test proceeded a lot was learned and we were able to adjust the equipment to operate faster.

Improvements are also to be made in dust management, because the camera and radar equipment on the remote-controlled machine were covered by dust quicker than anticipated. The backfill installation procedure qualification test was carried out in the 50-metre long tunnel used for the Trial Run of Final Disposal (TRFD). The remaining 40 metres of the tunnel will be filled in the actual Trial Run of underground operation, before the tunnel is finally sealed.

Equipment moved to Pori testing station next

Both the backfill installation system and the AGV vehicle platforms which move the system will next be transferred to the Pori testing station. There, the equipment will undergo maintenance and improvements based on the identified development needs. The procedure qualification test of backfill installation was carried out by a team of some ten individuals; 5 operators, the test supervisor, and systems experts.

The next installation procedure qualification tests will focus on testing the buffer installation system as well as the canister transfer and installation vehicle. These installation procedure qualification tests will be carried out as the last ones, and in practice parallel with each other, before the actual underground stage of the Trial Run of Final Disposal.

Read more: Test operation – Countdown to starting final disposal

Text: Pasi Tuohimaa, photos: Janne Anoschkin, Tapani Karjanlahti